With the increase in global healthcare spending and advances in medical technology, the medical device packaging market continues to expand.

Due to the particularity of medical devices, it has high requirements for packaging materials, and the use of thermoforming packaging machine has the following advantages

High protection and blocking barrier:

Aseptic operation and sterilization adaptability:

Reduce costs and improve efficiency

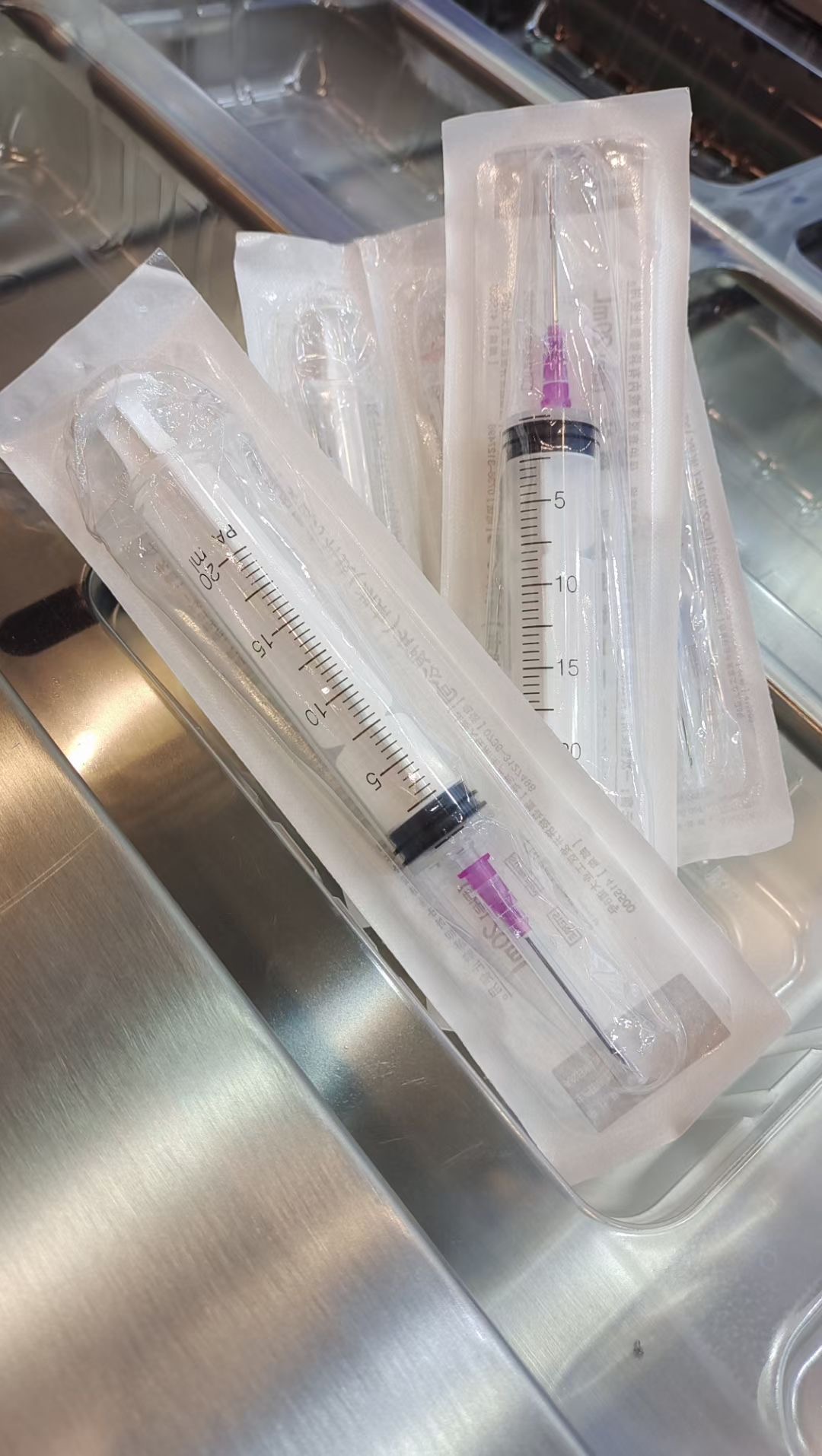

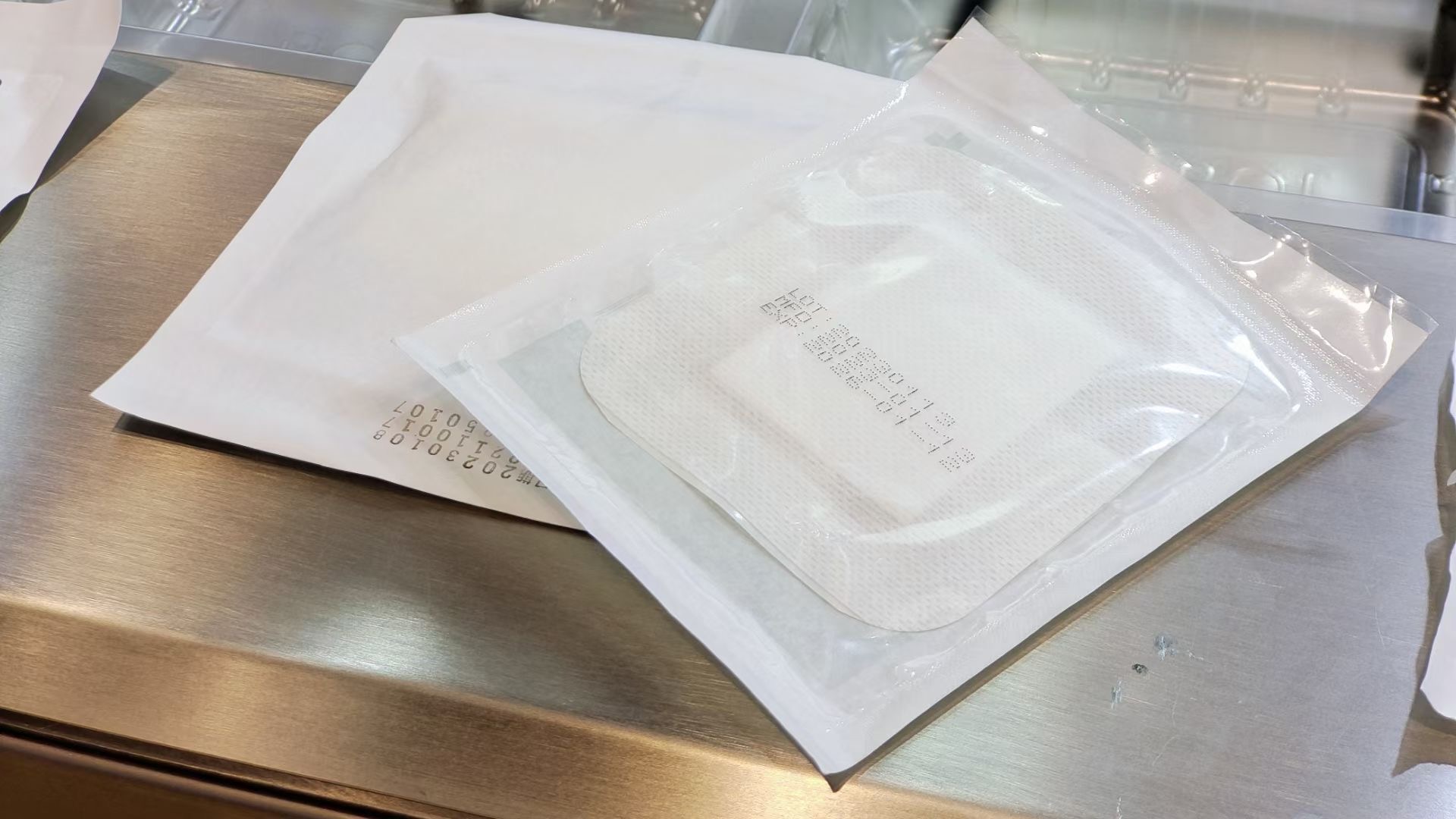

The thermoforming packaging machine is divided into soft film thermoforming packaging machine and rigid film thermoforming film packaging machine, which can be packed for different kinds of medical supplies.

Why choose the thermoforming packaging machine made by RODBOL?

Ethercat Bus Technology

• Adopt the latest EtherCAT bus technology to realize intelligent production.

• Has good scalability.

• Remote maintenance possible. Drive System: • Using servo drive, the positioning accuracy can reach 0.1mm. • Servo system precisely drives the chain for precise positioning.

• Smooth movement, no noise, efficient, stable and reliable operation.

Data protection:

• Adopt UPS power-off protection control system.

• Intelligent error diagnosis and operation guidance prompts.

• The electrical cabinet is equipped with constant temperature and dehumidification, and the grid monitoring is digitized.

Sealing System:

• Active film feeding structure + swing arm tensioning structure + film position adjustment structure + film braking structure + cursor detection system + patented cantilever.

• Using German JSCC motor, the film feeding is precise and wrinkle-free.

• Easy and quick film replacement.

RODBOL has always insisted on quality in the packaging industry, and looks forward to contributing to the sustainable development of the packaging industry in the future!

TEL:+86 152 2870 6116

E-mail:rodbol@126.com

Post time: Aug-08-2024