Products

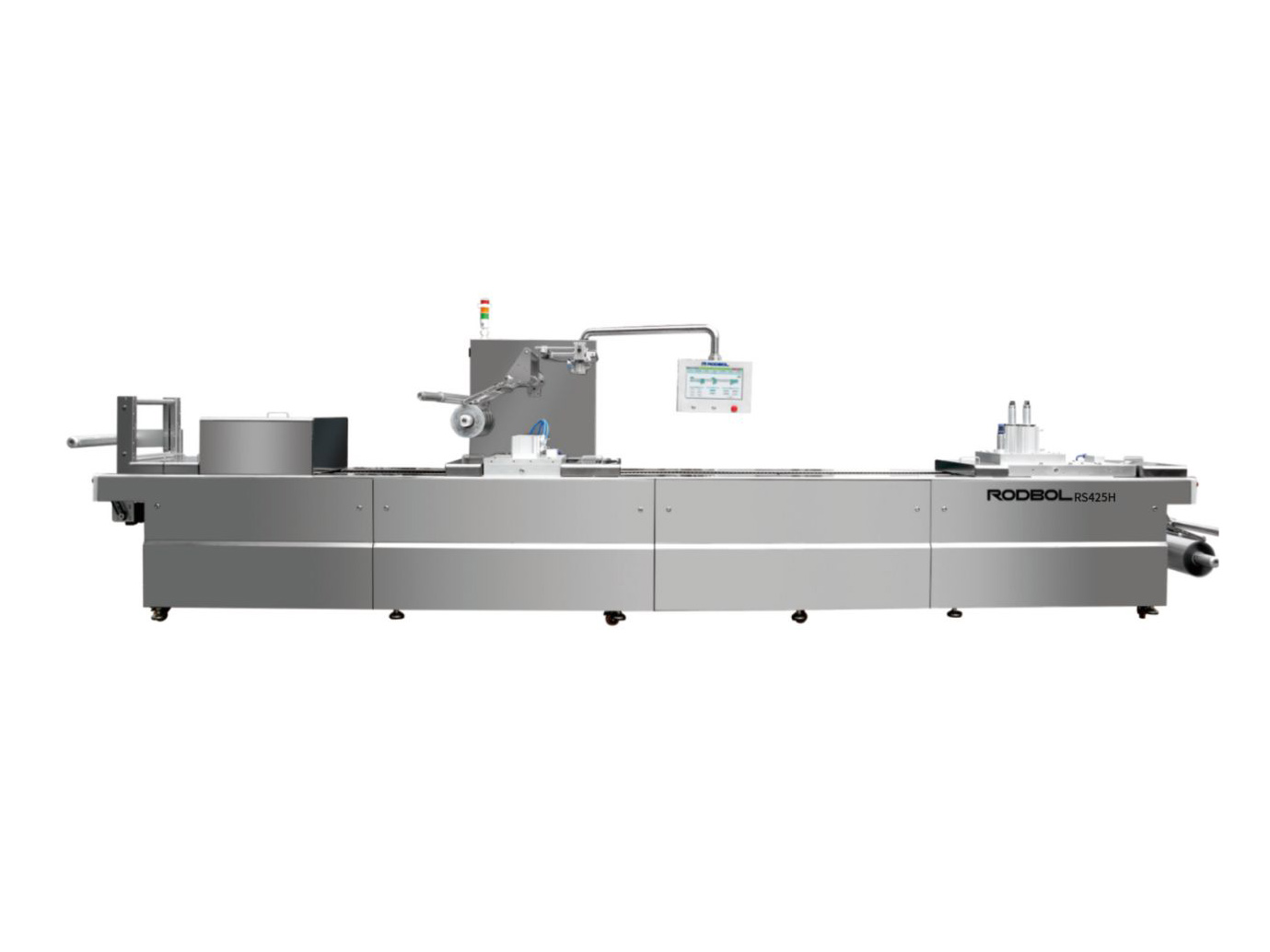

RS425H Thermoforming Machine -Rigid Bottom Film

Product Description

The Automatic Thermoforming Packaging Machine, tailored for large-scale mass-production utilizing Modified Atmosphere Packaging (MAP), encompasses a comprehensive array of components. This machinery comprises a sturdy Framework, an Automated Mold, a Gas-Mixer, a Freshness-Preserving Gas Displacement System, a Rigid Film Feed Mechanism, a Cover Film Delivery System, a Waste Film Recycling Mechanism, an Efficient Sealing System, an Automatic Conveyor, and an Advanced Servocontrol System. Its versatility extends across diverse sectors, including fresh and cooked meats, fruits & vegetables, seafood, central kitchens, dry foods, daily chemicals, pharmaceuticals, and even ice cream.

In today's rapidly evolving product enviroment, the pursuit of efficient and innovative packaging methodologies has intensified. Thermoforming packaging machines have revolutionized the industry, catering to the dynamic demands of consumers. This state-of-the-art technology boasts a versatile tray sealer that employs rigid base films for Modified Atmosphere Packaging (MAP), offering tailored packaging solutions to a broad spectrum of industries.

Specification

|

Type RS425H |

|||

| Dimensions (mm) | 7120*1080*2150 | The largest bottom film (widthmm) | 525 |

| Size of Molding(mm) | 105*175*120 | Power supply (V / Hz) | 380V,415V |

| One cycle time(s) | 7-8 | Power (KW) | 7-10KW |

| Packing speed (trays / hour) | 2700-3600(6trays/cycle) | Height of Operation(mm) | 950 |

| Touchscrren height(mm) | 1500 | Air source (MPa) | 0.6 ~ 0.8 |

| Length of Packing Area(mm) | 2000 | Container Size(mm) | 121*191*120 |

| Transmission method | Servo motor drive | ||

Why choose us?

Ethercat Bus Technology

• Adopt the latest EtherCAT bus technology to realize intelligent production.

• Has good scalability.

• Remote maintenance possible. Drive System: • Using servo drive, the positioning accuracy can reach 0.1mm. • Servo system precisely drives the chain for precise positioning.

• Smooth movement, no noise, efficient, stable and reliable operation.

Data protection:

• Adopt UPS power-off protection control system.

• Intelligent error diagnosis and operation guidance prompts.

• The electrical cabinet is equipped with constant temperature and dehumidification, and the grid monitoring is digitized.

Sealing System:

• Active film feeding structure + swing arm tensioning structure + film position adjustment structure + film braking structure + cursor detection system + patented cantilever.

• Using German JSCC motor, the film feeding is precise and wrinkle-free.

• Easy and quick film replacement.